Factory wholesale Hydroxypropyl Methyl Cellulose For Drymix Mortar - hydroxy methyl propyl cellulose – Wangjie

Factory wholesale Hydroxypropyl Methyl Cellulose For Drymix Mortar - hydroxy methyl propyl cellulose – Wangjie

Factory wholesale Hydroxypropyl Methyl Cellulose For Drymix Mortar - hydroxy methyl propyl cellulose – Wangjie Detail:

|

Classification |

Chemical Auxiliary Agent |

|

Place of Origin |

Heibei,China |

|

Type |

Carbon Black |

|

Usage |

Coating Auxiliary Agents, Electronics Chemicals, Leather Auxiliary Agents, Petroleum Additives, Surfactants, Textile Auxiliary Agents, Water Treatment Chemicals |

|

CAS No. |

9004-65-3 |

|

Other Names |

HPMC |

|

MF |

C12H20O10 |

|

Purity |

98% |

|

Brand Name |

WangJie |

|

Model Number |

Powder |

|

Tile |

hydroxy methyl propyl cellulose hpmc 100000 cps |

|

Product name |

Hydroxypropyl methyl cellulose |

|

Product name 2 |

HPMC |

|

viscosity |

3000-200000mpa.s |

|

Application |

construction mortar,putty |

|

Color |

Sub-white,white |

|

Appearance |

White Powder |

|

Material |

Cotton |

|

Certification |

ISO9001:2008 |

|

Item |

High Viscosity |

Tile Adhesive

1.Using HPMC, tile adhesive will easy to mix with water without lump appeared and saving time. Due to the more rapid and efficient operation, we can improve the workability and reduce the cost.

2.The water-retaining property of HPMC extend the drying time of mortar, so as to improve the efficient of fixing.

3.HPMC provide good bonding effect with highly skid resistance.

Cement-based plastering Mortar

1.HPMC can improve the uniformity of plastering mortar, making it easy to coating, at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

2.With high water retention, HPMC can prolong the working time of mortar, improve work efficiency, and help the mortar obtaining high mechanical strength in solidification period.

3.HPMC can control air infiltration, to eliminate the tiny cracks of coating, to format the ideal smooth surface.

Masonry mortar

1.HPMC can improve the adhesiveness between mortar and masonry. And the water-retaining property of HPMC is useful in raising the strength of mortar.

2.HPMC improves the lubricity and plasticity of mortar, so as to make the construction easier, to save time, to reduce the cost.

3.For superabsorbent masonry, it is more important to use HPMC in the mortar.

Crack filler

1.Excellent water retention of HPMC can prolong drying time of crack filler, it is helpful to improve work efficiency. Also, the high lubricity makes construction easier and more smooth.

2.HPMC can improve the shrinkage resistance and crack resistance of crack filler, to perfect the surface quality.

3.HPMC makes the construction surface fine and smooth. Meanwhile, the adhesiveness get improved.

Gypsum-based plastering and gypsum products

1.HPMC can improve the uniformity of plastering mortar, making it easy to coating, at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

2.With high water retention, HPMC can prolong the working time of mortar, improve work efficiency, and help the mortar in obtaining high mechanical strength in solidification period.

3.HPMC can keep the consistency unified, forming a good surface.

Self-leveling floor materials

1.The viscosity of HPMC has the effect of anti precipitation.

2.HPMC can enhance the product liquidity and pumpability, so as to improve the efficiency of the flooring.

3.The water-retaining property of HPMC can avoid excess air infiltration. Therefore, crack and contraction are greatly reduced.

Water-based paint and paint remover

1.The suspension property of HPMC can prolong expiration date by prevent solid precipitation. Meanwhile, it has good compatibility with other ingredients and biological stability.

2.HPMC helps the product dissolving rapidly without lump.

3.HPMC makes coating has good flow property and low splash, resulting a fine and smooth surface.

4.HPM can increase the viscosity of the paint remover, make it not out of work scope.

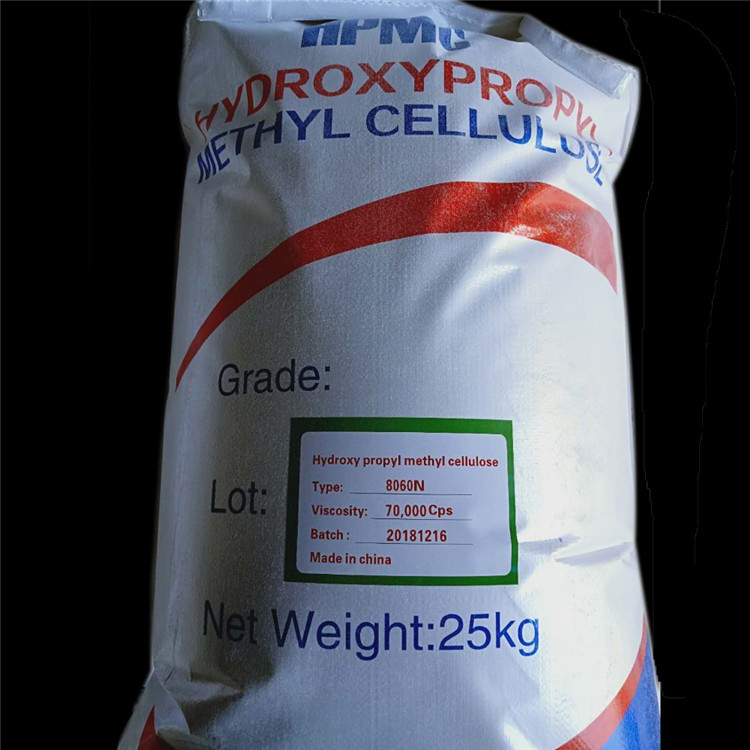

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Factory wholesale Hydroxypropyl Methyl Cellulose For Drymix Mortar - hydroxy methyl propyl cellulose – Wangjie , The product will supply to all over the world, such as: Vietnam, Gambia, Algeria, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!